Laboratory Radar

Innovation in the service of safety.

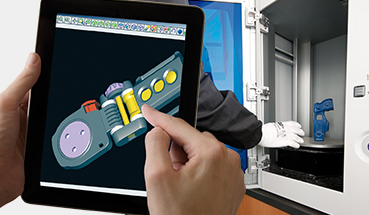

Research aimed at the development of new products and the perfection of existing products is a fundamental component in the constant evolution of Radar 1957 and in its worldwide success. Toachieve this aim we have invested vast resources in the creation the internal “Radar3 Cube” – Radar Research Resources laboratory.